Hoses are one of the essential tools we use in our gardens and lawns. They make watering our plants, cleaning sidewalks and driveways, and washing our cars easier. However, a disorganized hose can be inconvenient when left out and tangled.

Properly wrapping your hose can save you time and energy in the long run and can extend its lifespan. In this blog post, we will give you a step-by-step guide to how to wrap a hose and make it ready for future use.

Can You Wrap a Hose?

Hoses are a must-have item in any garden, allowing you to effortlessly water your plants and keep them looking green and healthy. But when storing them away, things can get a little tricky. Wrapping a hose might seem easy, but the number of times you’ve ended up with a tangled mess of tubing might suggest otherwise.

However, fear not! With a little bit of patience and following some helpful tips, even the most tangled hose can be wrapped up neatly and stored away, ready for its next use. So don’t let the tangled mess deter you from the joys of gardening; with some practice, you’ll be a pro at wrapping up your hose in no time.

Why Should You Wrap a Hose?

Wrapping your hose may seem simple, but it can make a big difference in the longevity and usability of your watering device. By wrapping your hose properly, you can prevent kinks, twists, and tangles that can cause damage and leaks. This can save you both time and money from having to replace your hose prematurely.

Additionally, wrapping your hose neatly and storing it in a protected area can protect it from weather and other external factors that can cause wear and tear. Whether you have a large or small garden, wrapping your hose is a quick and easy way to maintain the quality of your equipment.

Step-by-Step Instructions on How to Wrap a Hose

Step 1: Measure the Hose

Before you start wrapping a hose, it is important to measure the length of the hose to know how much material you will need. This will help ensure that your hose is properly wrapped and secure.

Step 2: Cut the Material

Once you have measured the length of your hose, cut the material that you are using for wrapping to size. Make sure to leave extra material on either end so that it can be secured with tape or adhesive.

Step 3: Wrap the Hose

Begin by wrapping one end of the hose with the material until it is completely covered. Make sure to wrap tightly so that there are no gaps between each layer of material. You may also want to use tape or adhesive to keep the layers in place as you wrap.

Step 4: Secure Ends

Once both ends of the hose are wrapped, secure them with tape or adhesive so that they do not come undone while in use. This will help ensure that your hose stays securely wrapped and does not become unwrapped during use.

Step 5: Check Wrapping

After securing both ends of your hose, check to make sure that it is evenly wrapped and there are no gaps between each layer of material. If necessary, adjust any areas where there may be gaps or looseness to ensure a snug fit around your hose when in use.

Step 6: Tape Seams

To further secure your wrapping job, use tape along all seams and edges where two pieces of material meet together or at any points where there may be a gap between layers of material. This will help ensure that your wrapping job is secure and won’t come undone during use or over time due to wear and tear from regular usage and exposure to elements such as sun, wind, rain, etc..

Step 7: Test Wrapping

Finally, test out your wrapping job by running water through it for several minutes before using it for its intended purpose (i.e., watering plants). This will help ensure that your hose is securely wrapped and won’t come undone during normal usage or when exposed to weather elements such as sun, wind, rain, etc.

5 Different Types of Hose Wraps

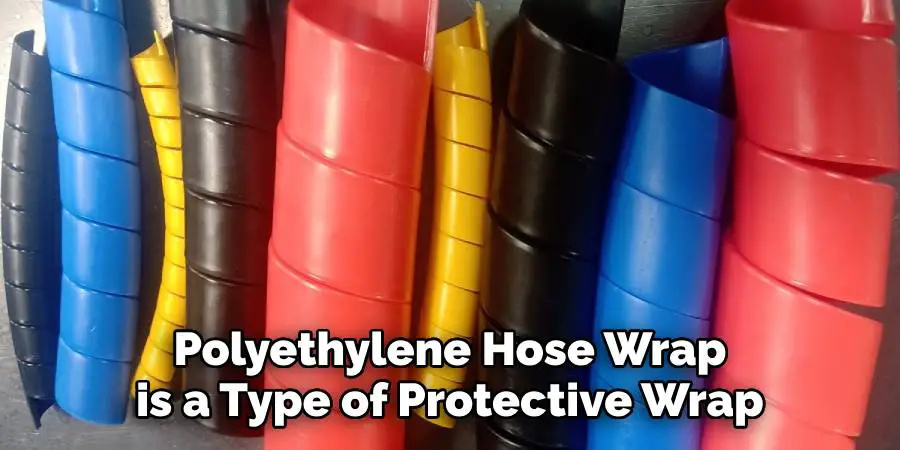

1. Polyethylene Hose Wrap

Polyethylene hose wrap is a type of protective wrap that is designed to protect hoses from abrasion and other types of damage. This type of hose wrap is often used in industrial and automotive applications where hoses are exposed to harsh environments. It is also resistant to most chemicals, making it a great choice for applications where hoses may come into contact with solvents or other corrosive materials.

2. PVC Hose Wrap

PVC hose wrap is another type of protective wrap that is designed to protect hoses from abrasion and other forms of damage. This type of hose wrap has the added benefit of being resistant to water and most chemicals. It is an ideal choice for applications where hoses may come into contact with liquids or corrosive materials.

3. Fiberglass Hose Wrap

Fiberglass hose wrap is a type of protective wrap that is designed to provide additional insulation for hoses in extreme temperature environments. This type of hose wrap can help prevent heat loss or gain, making it an ideal choice for applications where temperatures may fluctuate drastically over time.

4. Kevlar Hose Wrap

Kevlar hose wrap is a type of protective wrap that is designed to provide additional protection against high-pressure systems and abrasive surfaces. This type of hose wrap can be used in applications where hoses are exposed to extreme pressure or friction, such as hydraulic systems or off-road vehicles.

5. Nylon Hose Wrap

Nylon hose wrap is a type of protective wrap that provides additional protection against abrasion and other forms of damage while also providing flexibility and strength. This type of hose wrap can be used in many different applications, including automotive, marine, and industrial settings where hoses may be exposed to harsh conditions or need extra flexibility due to their design or installation requirements.

How to Choose the Right Hose Wrap for Your Needs

When choosing the right hose wrap for your needs, there are several factors to consider. These include the type of material you need, the required protection level, and the specific application for the hose. For example, if you need a hose wrap that is resistant to chemicals or abrasion, polyethylene or PVC may be the best choice.

Fiberglass may be more suitable if you need additional insulation for extreme temperatures. Additionally, considering costs and durability can help make an informed decision when selecting a hose wrap.

5 Tips for Wrapping a Hose

1. Measure the Hose

Before you start wrapping your hose, it is important to measure its length and width to determine how much material you will need. It is also important to measure the circumference of the hose to determine which size wrap will be most suitable. Make sure to leave a few extra inches of material when measuring, as this will give you some extra room for securing the end of the wrap.

2. Choose an Appropriate Material

When selecting a material for wrapping your hose, ensure it is strong enough to withstand the elements and any potential wear and tear. Common materials used for wrapping hoses include nylon webbing, polyester strapping, and vinyl-coated polyester mesh. Each material has its own advantages and disadvantages; make sure to choose one that best suits your needs.

3. Cut the Material

Once you have selected a suitable material for your hose wrap, cut it into pieces that are long enough to cover the length of your hose with some extra room at each end for securing it in place. If using multiple pieces of material, make sure they are all cut to the same length to fit together properly when wrapped around the hose.

4. Secure One End

To begin wrapping your hose, secure one end of the material in place by using cable ties or zip ties. This will ensure that everything stays in place while you are wrapping it around the hose. Make sure not to use too many ties, as this can restrict movement and cause damage to both your hose and wrap over time.

5. Wrap Around Hose

Once one end is secured in place, start wrapping your material around the hose from top to bottom until it is completely covered with no gaps or spaces between wraps. When finished, secure the other end in place using cable ties or zip ties before trimming off any excess material if necessary.

How to Wrap a Hose for Repairs

When it comes to repairing a damaged hose, wrapping it properly is key to getting the job done efficiently. First, inspect the hose for any punctures, cracks, or kinks and mark them with a permanent marker. Then, start wrapping a nylon thread or tape around the hose tightly, ensuring that it overlaps itself.

This will create a secure layer of protection around the damaged area. Be sure to wrap several inches beyond the marked area to fully prevent any leaks. Once wrapped, cut the thread or tape carefully and secure the ends with a knot or tape. With these steps, you can repair a damaged hose and ensure it lasts for many more washes, watering sessions, or other jobs.

Conclusion

Wrapping a hose might seem simple, but it can make all the difference regarding the hose’s longevity and usefulness. Properly wrapping your hose will keep it organized and tidy for future use. Follow these easy steps, and you can wrap your hose like a pro in no time. With a bit of practice, you will find that the process will be effortless and become an essential part of your post-gardening routine. Thanks for reading our post about how to wrap a hose, and happy gardening!