The toilet fill valve plays a crucial role in the proper functioning of a toilet system. It is responsible for refilling the toilet tank with water after each flush, ensuring that the toilet is ready for subsequent use. Understanding how a toilet fill valve works is essential for diagnosing issues such as leaks, slow refills, or complete failure to fill. In this guide, we will explore the how toilet fill valve works, how it operates, and tips for maintenance, helping you to keep your toilet functioning efficiently.

What is a Toilet Fill Valve?

A toilet fill valve, also known as a ballcock, is a mechanical device located within the toilet tank. Its primary function is to regulate the flow of water into the tank after a flush. When the toilet is flushed, the fill valve is activated, allowing water to flow from the supply line into the tank until it reaches the predetermined level. This valve typically consists of a float mechanism that rises and falls with the water level, shutting off the water flow once the tank is adequately filled. Understanding the components and operation of the toilet fill valve can help homeowners quickly identify and address problems, ensuring their toilet performs optimally.

Components of a Toilet Fill Valve

A toilet fill valve comprises several key components that work together to ensure its proper function. The main parts include:

- Float: This is a buoyant device that rises and falls with the water level in the tank. As the tank fills, the float ascends until it reaches a specific height, at which point it signals the valve to shut off the water supply.

- Inlet Valve: This component controls the flow of water from the supply line into the toilet tank. When activated by the float’s movement, the inlet valve opens to allow water to fill the tank.

- Shut-Off Mechanism: This mechanism is triggered by the float when the tank reaches its predetermined fill level. It stops the water flow to prevent over-filling.

- Adjustment Screw: Many fill valves feature an adjustment screw that allows users to alter the height at which the float shuts off the water supply. This adjustment ensures the tank fills to the desired level, optimizing performance.

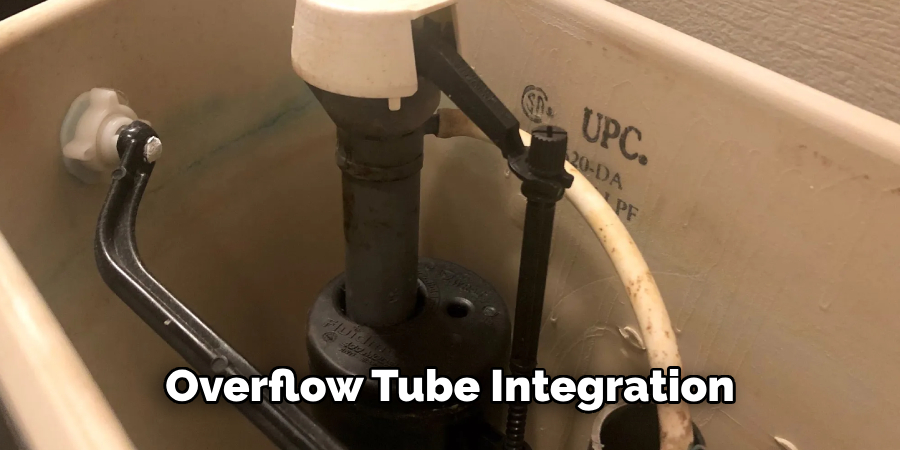

- Overflow Tube: This tube prevents the tank from overflowing by directing excess water into the bowl if the fill valve fails and the water level rises too high.

Understanding these components aids in troubleshooting and repairs, allowing for effective maintenance of the toilet fill valve and the overall toilet system.

10 Methods How Toilet Fill Valve Works

1. Water Inlet Mechanism

The water inlet mechanism is the first part of the fill valve that initiates the refilling process. When the toilet is flushed, water drains from the tank into the bowl, and the fill valve opens to allow fresh water to flow from the water supply line into the tank. The inlet mechanism is connected to the household’s plumbing through a supply line, and water pressure pushes the water through the valve. The amount of water that flows into the tank is regulated by the valve, which will continue to fill the tank until it reaches the proper water level. This process begins the moment the flush lever is activated.

2. Float Assembly

The float assembly plays a vital role in controlling the fill valve. As the tank empties during a flush, the float drops with the water level. This drop triggers the fill valve to open and begin refilling the tank. As the tank fills back up with water, the float rises accordingly. Once it reaches the preset water level, the float assembly signals the fill valve to shut off, stopping the water flow. Floats can come in different designs, such as ball floats attached to an arm or more modern cup-style floats. The precise movement of the float ensures that the correct amount of water is refilled after each flush.

3. Fill Valve Shutoff Mechanism

The shutoff mechanism is responsible for stopping the water flow once the tank reaches the desired level. It’s an integral part of how the fill valve works, ensuring no water overflows into the toilet tank. When the float assembly reaches the preset water level, the shutoff mechanism closes the valve. This halts the inflow of water from the supply line. The shutoff function is crucial for conserving water and preventing overflow, ensuring that your toilet fills only to the necessary level. If the valve fails to shut off, it could result in a constantly running toilet, wasting water and potentially leading to higher utility bills.

4. Overflow Tube Integration

The overflow tube is a safeguard built into the toilet’s fill system to prevent the tank from overflowing if the fill valve fails to shut off. The fill valve works in tandem with the overflow tube to ensure excess water is diverted safely into the toilet bowl, rather than spilling over the top of the tank. The tube is positioned in the center of the tank and is open at the top, allowing water to flow into it if the water level rises too high. While the overflow tube is rarely engaged under normal conditions, it serves as an essential backup to protect your bathroom from water damage in case of a malfunctioning fill valve.

5. Refill Tube Functionality

The refill tube is another crucial component of the fill valve system that helps to refill the toilet bowl after a flush. As the fill valve refills the tank, a small amount of water is directed through the refill tube into the overflow tube, which in turn refills the bowl. This ensures the correct amount of water is in the bowl after each flush, which is vital for proper toilet operation. Without the refill tube, the bowl would not refill correctly, leading to poor flushing performance. The refill tube works in coordination with the fill valve and must be positioned properly for optimal function.

6. Water Pressure Regulation

Water pressure plays an important role in how the fill valve works. The fill valve is designed to regulate the amount of water flowing into the tank, regardless of fluctuations in household water pressure. If the water pressure is too high, the valve restricts the flow to prevent overfilling or damage to the valve itself. Conversely, if the pressure is too low, the valve ensures that water still flows into the tank at an adequate rate, albeit more slowly. This regulation maintains consistent toilet operation even when water pressure varies.

7. Float Adjustment for Water Level Control

The ability to adjust the float is a feature that allows for fine-tuning of the water level inside the tank. By adjusting the float, you can control how much water the fill valve allows into the tank. If you want to save water or if your tank is overfilling, you can lower the float so that the valve shuts off sooner, reducing the amount of water in the tank. Conversely, if your flushes aren’t clearing the bowl adequately, raising the float allows more water into the tank. Float adjustment ensures that your toilet operates efficiently and flushes effectively.

8. Anti-Siphon Feature

Many modern fill valves come with an anti-siphon feature, which prevents backflow from the toilet tank into the water supply. This is an important safety feature that protects the potable water supply from contamination. During the refilling process, the anti-siphon valve ensures that water flows only into the tank, without any possibility of tank water being siphoned back into the household plumbing. The anti-siphon mechanism works automatically and is essential in maintaining a hygienic and safe water system.

9. Air Venting Mechanism

Fill valves are equipped with an air venting system that ensures smooth water flow into the tank. As the tank fills, air must escape to allow water to flow in freely. The air venting mechanism ensures that air bubbles do not form in the water supply line, which could cause the fill valve to malfunction or create a sputtering effect as water enters the tank. This venting system allows the water to flow into the tank uninterrupted and helps maintain the efficiency of the toilet’s refill cycle.

10. Maintenance and Cleaning

To keep a fill valve functioning properly, regular maintenance is necessary. Over time, debris, sediment, and mineral buildup can accumulate inside the valve, restricting water flow and causing the valve to work improperly. Cleaning the fill valve periodically helps prevent clogs and ensures the valve operates efficiently. To clean the valve, turn off the water supply, remove the valve, and disassemble the components. Use a brush or cloth to remove any buildup, then reassemble and reinstall the valve. Proper maintenance can extend the life of the fill valve and prevent the need for frequent replacements.

Conclusion

A toilet fill valve is an intricate mechanism that controls how water flows into the tank after each flush. Its components, including the water inlet, float assembly, shutoff mechanism, overflow tube, and refill tube, all work together to ensure the toilet operates smoothly and efficiently. Understanding how these parts function will not only help you maintain your toilet but also enable you to troubleshoot and repair any issues that may arise. Thanks for reading, and we hope this has given you some inspiration on how toilet fill valve works!