Are you looking for an efficient and cost-effective way to repair drains or sewer pipes? Pipe lining technology is a revolutionary new system that eliminates the need for costly dig-ups and traditional pipe repairs.

By utilizing specialized epoxy resins, this advanced process creates a seamless, jointless tubular inside surface of high-strength composite materials allowing any existing pipe to be effectively rehabilitated without replacing it completely.

In this blog post, we’ll dive into how does pipe lining work, its many benefits, and potential applications for drain repairs. Read on to learn more about this innovative solution!

What is Pipe Lining?

Pipelining, also known as cured-in-place pipe (CIPP) lining, is a trenchless technology used to restore and rehabilitate underground pipes without having to dig up the existing damaged pipe.

The process involves creating a new pipe within an old one by inserting a flexible resin-coated tube into the damaged pipe, then inflating it and curing it in place using hot water or UV light. Once cured, the result is a durable and seamlessly lined pipe within the existing one. This new inner layer essentially creates a pipe within a pipe.

Step-by-step Process on How Does Pipe Lining Work

Step 1: Pipe Inspection

The first step in the pipe lining process is to conduct a thorough inspection of the existing pipe using specialized cameras and equipment. This allows technicians to identify any cracks, holes, or blockages that need to be addressed before proceeding with the pipelining process. This step is crucial to ensure that the lining process will be effective and long-lasting.

Step 2: Pipe Cleaning

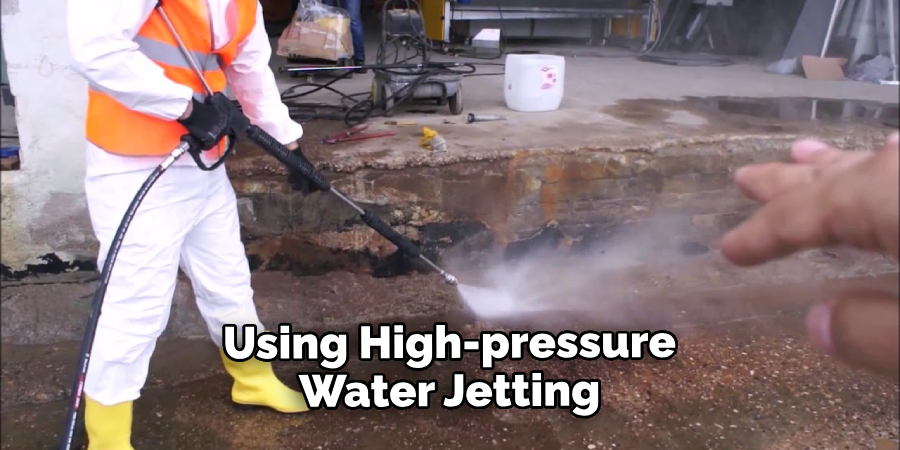

Once any necessary repairs are completed, the next step is to clean the existing pipe using high-pressure water jetting or mechanical cleaning tools. This removes any debris or corrosion from the inside of the pipe, creating a smooth surface for the lining to adhere to. Pipe cleaning is crucial to ensure the success of the pipelining process. Carefully cleaned pipes will result in a more durable and long-lasting lining.

Step 3: Pipe Lining Installation

After the pipe is thoroughly inspected and cleaned, the lining process can begin. A flexible tube coated with epoxy resin is inserted into the damaged pipe using specialized equipment, such as air compressors or winches.

Once in place, the tube is inflated to adhere to the inside of the pipe, and then cured in place using hot water or UV light. The curing process typically takes a few hours, after which the new lining will be fully hardened and ready for use.

Step 4: Pipe Reinspection

After the lining has been cured, a final inspection is conducted to ensure that all repairs were successful and no leaks or damage remains. Once the pipe has passed inspection, it is ready to be put back into use. Make sure to consult with your pipelining technician on recommended maintenance and care for the newly lined pipe.

By following these four simple steps, pipe lining can efficiently and effectively rehabilitate damaged pipes without the need for costly excavation. You can save time, money, and the hassle of traditional pipe replacement by using this innovative technology.

Benefits of Pipe Lining

1. Increased Efficiency:

The main advantage of pipelining is that it boosts the efficiency of a process. By breaking down the process into smaller, specialized tasks and assigning them to different workers or machines, pipe lining allows for faster completion of work. This will help in saving time and increasing productivity.

2. Better Resource Utilization:

Pipelining also allows for better utilization of resources. By allowing different tasks to be performed simultaneously, it reduces idle time and ensures that resources are being utilized efficiently. This not only saves money but also helps in getting more work done with the same amount of resources.

If one task requires more resources while others are idle, the pipeline can automatically allocate those resources to complete the task faster. This improves resource management and results in overall cost savings.

3. Improved Quality Control:

Pipelining also helps in maintaining high-quality standards for the end product. By dividing the process into smaller tasks, it allows for easier monitoring and evaluation of each step. Any issues or errors can be identified and corrected early on, reducing the chances of major defects in the final product. This is especially beneficial in manufacturing and production processes where quality control is critical.

4. Flexibility and Scalability:

One of the key benefits of pipe lining is its flexibility and scalability. As different tasks are broken down into separate steps, it becomes easier to modify or add new tasks as needed.

This makes it ideal for industries that require frequent changes or modifications in their processes. Additionally, pipe lining also allows for easy replication of tasks, making it easier to scale up production when needed.

5. Cost Savings:

Pipelining can result in significant cost savings for businesses. By increasing efficiency and improving resource utilization, it reduces operational costs and increases profits. It also helps in reducing wastage and minimizing errors, leading to further cost savings over time. This makes pipe lining an attractive option for businesses looking to improve their bottom line.

6. Reduced Waiting Time:

In traditional sequential processes, there is a lot of waiting time between each step as tasks are completed one after the other. With pipe lining, there is no need to wait for one task to be completed before starting the next one. This results in a significant reduction in waiting time, allowing for faster completion of work.

7. Increased Throughput:

Pipelining also leads to increased throughput or output per unit of time. By breaking down a process into smaller steps and performing them simultaneously, more work can be completed in less time. This is particularly beneficial in industries with high demand and tight deadlines. This increased throughput can lead to better customer satisfaction and increased profits for businesses.

These are just some of the many benefits of pipelining. With its ability to improve efficiency, reduce costs, and increase throughput, it has become an essential tool in various industries. From manufacturing and production to software development and data processing, pipelining has revolutionized the way processes are completed.

So if you want to streamline your operations and stay ahead in today’s competitive market, consider implementing pipe lining in your processes. So don’t wait any longer and start reaping the benefits of pipe lining today!

Disadvantages of Pipe Lining Work

1. Increased Complexity:

Pipe lining involves breaking down instructions into smaller stages and executing them simultaneously. This increases the complexity of the design and implementation process, making it more difficult to troubleshoot and maintain. This complexity can also lead to errors and bugs, which can be challenging to locate and fix.

2. Resource Management:

Pipelining requires careful resource management to ensure that each stage of the pipeline has access to the necessary resources at the appropriate time. This can be tricky, especially in cases where multiple instructions are competing for the same resources. Improper resource management can result in performance issues and bottlenecks.

3. Dependency Between Stages:

As each stage of the pipeline is dependent on the previous one, any delay or interruption in one stage can affect the entire process. This means that if one instruction encounters an error or a cache miss, all subsequent instructions will have to wait for it to be resolved before they can proceed. This dependency can limit the benefits of parallel processing and slow down overall performance.

4. Difficult to Implement for All Instructions:

Not all instructions can be effectively divided into smaller stages for pipelining. Some instructions may depend on the results of previous instructions, making it difficult to split them into independent stages. In such cases, pipe lining cannot be utilized, leading to inefficient use of resources and potential performance issues.

5. Costly Implementation:

Implementing pipeline architecture can be expensive, both in terms of time and resources. It requires specialized hardware and software to support the parallel processing of instructions. Moreover, the design and implementation process may require extensive testing and optimization to ensure optimal performance, adding to the overall cost.

These are the main disadvantages of pipe lining work that should be considered when deciding whether to implement this technique. While pipeline processing can significantly improve performance and efficiency in certain cases, it is not without its drawbacks.

Careful consideration of these factors is necessary to determine if pipe lining is the right approach for a given computing task. So, before implementing pipeline architecture, it’s important to weigh both the advantages and disadvantages to make an informed decision.

Frequently Asked Questions

How Can I Improve the Pipeline Efficiency?

Improving pipeline efficiency can be achieved through a variety of methods. Some possible solutions include implementing parallel processing, using predictive analytics to forecast resource needs, optimizing task distribution and allocation, and continuously monitoring and updating the pipeline design. Additionally, regularly analyzing bottlenecks and identifying areas for improvement can also help to enhance the overall efficiency of your pipeline.

Are There Any Tools Available to Help With Pipeline Management?

Yes, there are various tools and software available that can aid in pipeline management. These tools often provide features such as task scheduling, resource allocation, performance monitoring, and visualization of the pipeline flow. Some popular examples include Airflow, Luigi, Apache NiFi, and Jenkins.

How Can I Ensure Data Quality Throughout the Pipeline?

Data quality is crucial for any pipeline to function effectively. To maintain data quality, it is essential to have proper data governance in place.

This involves setting up standards and protocols for data handling, establishing checkpoints for data validation, and performing regular audits to identify and correct any errors or inconsistencies. Additionally, implementing automated testing and validation processes can also contribute to maintaining data quality throughout the pipeline.

What Steps Should I Take if the Pipeline Fails?

Pipeline failures can occur due to various reasons, such as coding errors, resource limitations, or data quality issues. When a pipeline fails, it is important to identify the root cause and take corrective actions promptly.

This may involve debugging the code, increasing resources, re-running failed tasks, or fixing data quality issues. It is also crucial to have proper error handling and logging mechanisms in place to quickly identify and address any failures that may occur.

Conclusion

Now you know how does pipe lining work and some ways to improve its efficiency, manage it, maintain data quality, and handle failures. By implementing these best practices and continuously monitoring and updating your pipeline design, you can ensure a smooth and efficient data processing workflow. As technology continues to evolve, new tools and strategies for pipeline management will also emerge, so it is essential to stay informed and adapt accordingly.

With an optimized pipeline, you can streamline your data processing and analysis, leading to better decision-making and business outcomes. So keep learning, experimenting, and optimizing your pipeline for maximum efficiency!