Are you looking to do some plumbing in your home but can’t seem to find a way around the dreaded kinking of pex tubing? You’re not alone. Every year, countless DIYers and plumbers alike struggle with working with pex pipes that keep getting kinked before they can be installed. Don’t worry – there’s a smarter, better way to bend pex without it ever becoming too tight or developing any kind of kinking!

In this blog post, we will explain how to bend pex without kinking by using special tools and procedures so that your next plumbing project goes smoothly! Read on for all the tips and tricks you need now when tackling even the toughest projects involving bending Pex.

Why May You Want to Bend Pex Without Kinking?

1 . To Save Money

Pex is a relatively inexpensive material, but it still costs money. If you end up kinking the tubing while bending it, you may need to cut and discard that section, which means spending more on additional tubing. By learning how to bend Pex without kinking, you can minimize waste and save money.

2 . To Prevent Leaks

A kink in Pex tubing can cause it to crack or expand, which may lead to leaks and other issues. If you’re installing Pex for plumbing purposes, preventing kinks is crucial to ensure a leak-free system. By following the proper bending techniques, you can eliminate the risk of future leaks and save yourself from costly repairs.

3 . To Avoid Delays in Installation

Kinking Pex can result in delays during installation, especially if you’re working on a tight schedule. You may have to stop and re-do certain sections, which can be time-consuming and frustrating. By bending Pex without kinks, you can ensure a smooth and efficient installation process.

How to Bend Pex Without Kinking in 5 Easy Steps

Step 1: Gather Your Materials

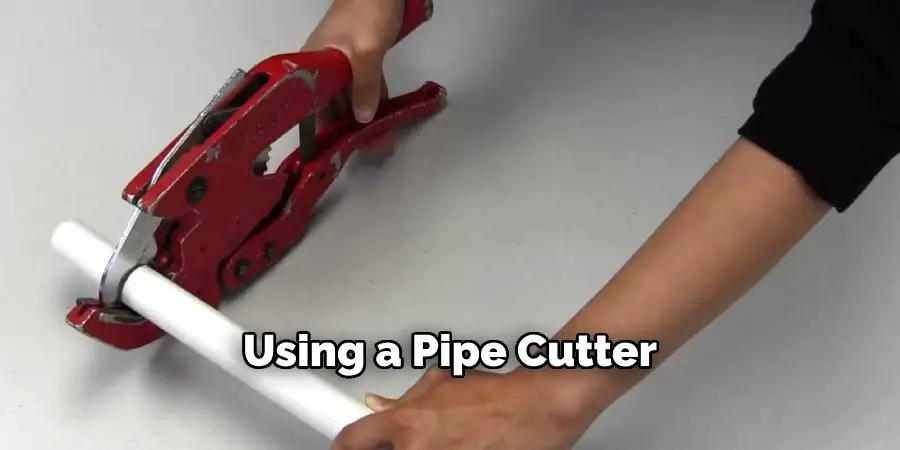

Before starting to bend Pex tubing, ensure you have all the necessary materials. These include a pipe cutter, deburring tool, heat gun or hairdryer, and clamps.

Step 2: Cut the Pex Tubing

Using a pipe cutter, make a clean cut on the end of the Pex tubing where you want to create the bend. Ensure that the cut is straight and free from any burrs.

Step 3: Insert a Spring into the Tubing

To prevent kinking, insert a spring into the Pex tubing before bending it. This will support the inner walls of the tube during the bending process and maintain its shape.

Step 4: Apply Heat

Using a heat gun or hairdryer, apply heat to the area of the tubing where you want to create the bend. Move the heat source back and forth along the tube evenly for about 30 seconds. Also, heat the tubing evenly on both sides to avoid warping.

Step 5: Bend the Pex Tubing

Once the tubing is heated and malleable, use your hands to gently bend it into the desired shape. Keep in mind that Pex tubing can only be bent up to a certain angle without risking damage or kinking. Use clamps to hold the tubing in place as it cools and sets into its new shape.

10 Tips for Bending Pex Without Kinking

1 . Choose the Right Type of Pex

Before bending Pex, it is essential to choose the right type of Pex for your project. There are three types of Pex: A, B, and C. Type A has an oxygen barrier and is suitable for hot water applications. Type B does not have an oxygen barrier and can be used for both hot and cold water applications. Type C is suitable for cold water applications only. Make sure to choose the appropriate type of Pex for your project to avoid any future problems.

2 . Use a Quality Bending Tool

Using a quality bending tool is crucial in preventing kinks when bending Pex. Investing in a reliable and durable bending tool will ensure that you can bend Pex efficiently and without any kinks. Cheaper bending tools may not have the necessary strength to bend Pex properly, leading to kinks.

3 . Keep the Bending Angle in Mind

When bending Pex, it is crucial to keep the desired bending angle in mind. This will help you maintain a smooth and even bend without putting too much strain on the Pex. It is recommended to use a bending tool with an angle guide to ensure precision in your bends.

4 . Heat the Pex Before Bending

One way to prevent kinks when bending Pex is by heating it before bending. This will make the Pex more pliable and easier to bend without any resistance or kinking. You can use a heat gun or a hairdryer to heat the Pex evenly before bending.

5 . Use Sand to Prevent Kinking

For sharper bends, using sand inside the Pex can help prevent kinking. Simply fill the Pex with sand before heating and bending. The sand will support the walls of the Pex and prevent it from collapsing or kinking during the bend. Once the Pex has cooled, you can easily pour out the sand.

6 . Avoid Using Too Much Force

When bending Pex, avoid using excessive force as it can cause kinks in the Pex. Let the bending tool do the work and apply gentle pressure to ensure a smooth bend. If you encounter resistance or feel like you are forcing the Pex, stop and reassess before proceeding.

7 . Use Pex Bending Springs

Pex bending springs are another useful tool in preventing kinks when bending Pex. These springs fit inside the Pex and provide support during the bend, reducing the risk of kinking. They come in various sizes to accommodate different pipe diameters.

8 . Bend Slowly and Gradually

Bending Pex too quickly or sharply can lead to kinking. It is essential to bend slowly and gradually, allowing the Pex to adjust to the new shape without any strain. This will ensure a smooth and even bend without any kinks.

9 . Don’t Overbend

Overbending Pex can also cause kinks. Be sure to bend the Pex to the desired angle without going past it. If you accidentally overbend, you can use a bending spring or heat gun to adjust and correct the bend without any kinks.

10 . Practice Makes Perfect

Lastly, like with any new skill, practice makes perfect. It may take a few tries before you can bend Pex without kinking, so be patient and keep practicing. With time and experience, you will become more comfortable and confident in bending Pex without any kinks. Remember to always use the appropriate tools and techniques for the best results.

As with any home improvement project, it is important to prioritize safety while bending Pex. Always wear protective gear such as gloves and eye protection, and be careful when working with heated Pex. By following these tips and taking your time, you can successfully bend Pex without any kinks for a professional and functional end result. So go ahead, confidently tackle that plumbing project and bend Pex like a pro!

Frequently Asked Questions

What Precautions Should I Take When Bending Pex Tubing?

Pex tubing is a flexible material that can be shaped into curves and angles without the need for elbow joints. However, it is important to take precautions when bending pex tubing to avoid kinks and damage.

To ensure successful results, here are some precautions you should take when bending pex tubing:

- Use a Pipe Bending Spring: A pipe bending spring is a flexible metal coil that you insert into the pex tubing before bending. This helps to support and distribute the stress of the bend, preventing kinks.

- Use Proper Tools: When bending pex tubing, make sure to use tools specifically designed for working with pex, such as a pipe cutter and crimping tool. These tools will ensure clean and precise cuts and crimps, reducing the risk of damage.

- Avoid Excessive Force: Pex tubing is designed to be flexible, but it has its limits. Applying excessive force when bending can cause kinks or even breakage. Use gentle and gradual pressure to create curves and angles.

- Keep the Temperature in Mind: Pex tubing is sensitive to temperature changes, so it’s important to consider the ambient temperature when bending. If the tubing is too cold, it may become brittle and prone to kinking. If it’s too hot, it may become too pliable and difficult to control.

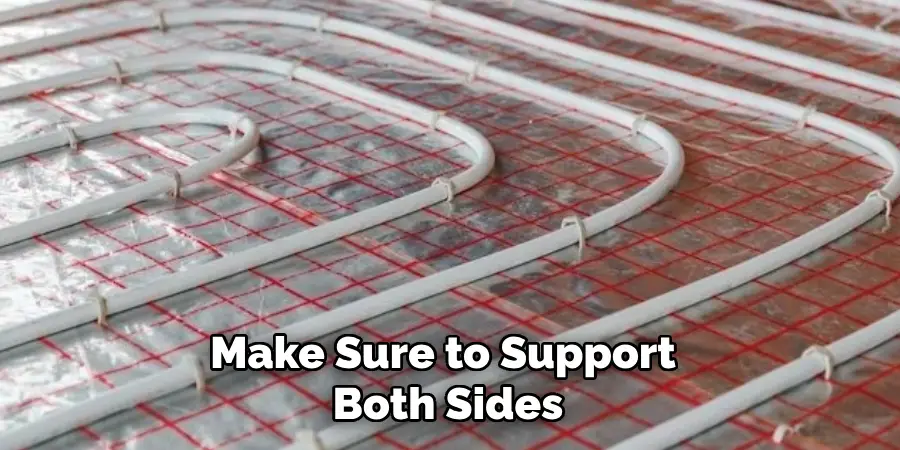

- Support the Bend: When creating a bend in pex tubing, make sure to support both sides of the bend to prevent it from collapsing or becoming misshapen. You can use your hand, a piece of wood, or other materials for support.

By taking these precautions, you can ensure that your pex tubing will be bent without kinking and maintain its structural integrity.

Can Pex Tubing Be Bent Multiple Times?

Yes, pex tubing can be bent multiple times without causing damage. However, it is important to avoid creating sharp bends or kinks when bending multiple times, as this can weaken the tubing and lead to failure. If you need to make multiple bends in a length of pex tubing, it’s best to do so gradually and evenly. This will help distribute the stress on the tubing and prevent any weak points from forming.

Can I Use a Heat Gun to Bend Pex Tubing?

While it is possible to use a heat gun to bend pex tubing, it is generally not recommended. The high heat from a heat gun can cause the pex tubing to become too pliable and difficult to control, leading to kinks or distortions. In addition, excessive heat can also damage the inner layers of the tubing, compromising its structural integrity. It’s best to use manual bending methods or a pipe bender designed specifically for pex tubing.

Conclusion

All in all, it is possible to bend pex pipe without kinking it. With the right tools and taking your time during installation, you can easily create smooth bends that will prevent water flow stoppage. As someone who has experience in bending large pipes, I can tell you that it is a skill that requires careful attention and patience. But with practice and persistence, anyone can achieve tight bends quickly and efficiently without damaging the plumbing system.

Now you know how to bend pex without kinking! So, if you’re looking for an efficient way to install new pex piping systems or replace existing ones, then utilizing the bending method outlined here could make your job much easier. Now that you know how to bend pex pipe without kinking it, why not try it for yourself? Put these tips into practice and become a pro at making perfect bends quickly!