Straightening copper tubing is a crucial skill for DIY enthusiasts, plumbers, and HVAC technicians, ensuring precision and efficiency in various installation and repair projects. Copper tubing, prized for its durability and versatility, often arrives in coils or rolls, which can be challenging to work with due to their tendency to retain bends and kinks.

Straightening copper tubing requires patience, proper technique, and the right tools to achieve smooth, uniform results without compromising the tubing’s integrity. Whether you’re installing water lines, refrigeration systems, or air conditioning units, straight copper tubing ensures optimal flow and performance. This guide will provide comprehensive instructions on how to straighten copper tubing effectively, covering techniques such as hand straightening, using bending springs, or employing specialized tools like tube straighteners.

Mastering the art of straightening copper tubing will enable you to tackle plumbing and HVAC projects with confidence and precision, achieving professional-quality results every time.

Understanding Copper Tubing

Copper tubing is a widely used material in plumbing and HVAC applications due to its reliability, ease of manipulation, and long-lasting properties. Available in various sizes and types, copper tubing can cater to a range of needs from residential plumbing to large-scale industrial systems. The main types of copper tubing include Type K, L, M, and DWV, each distinguished by wall thickness and intended use.

Type K has the thickest walls and is often used for underground or high-pressure applications, while Type L, with moderately thick walls, is commonly used in interior plumbing. Type M, having the thinnest walls, is typically suitable for low-pressure scenarios, and DWV (Drain, Waste, and Vent) is designed specifically for non-pressure applications in drainage systems.

Copper’s natural resistance to corrosion and its ability to withstand high and low temperatures make it an ideal choice for both hot and cold water supply lines, as well as for refrigerant lines in HVAC systems. Additionally, copper’s antimicrobial properties add to its appeal in healthcare and food processing environments. Understanding the different types of copper tubing and their specific applications can help ensure that the right material is chosen for each project, facilitating efficient and safe installations.

10 Methods How to Straighten Copper Tubing

1. Understanding Copper Tubing

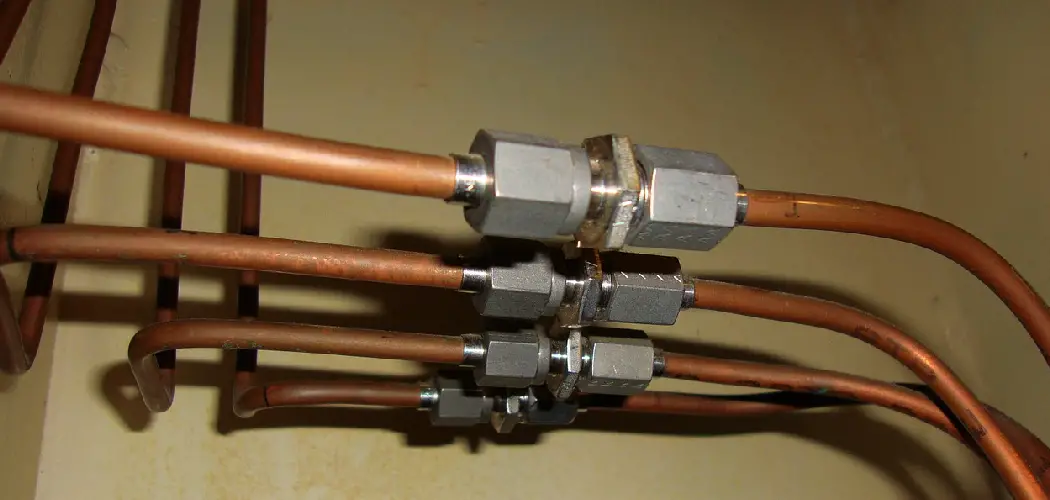

Before straightening copper tubing, it’s essential to understand its properties and characteristics. Copper tubing is a durable and malleable material commonly used in plumbing and HVAC applications due to its corrosion resistance and thermal conductivity. Copper tubing comes in various sizes and types, including rigid copper tubing, soft copper tubing, and copper coil. Familiarizing yourself with the type of copper tubing you’re working with ensures you use the appropriate straightening method and avoid damaging the tubing.

2. Assessing the Condition of the Tubing

Before attempting to straighten copper tubing, assess its condition to determine the extent of the bends or kinks. Inspect the tubing for any visible deformities, such as bends, twists, or creases. Determine whether the tubing is rigid or soft, as this will influence the straightening method you use. Soft copper tubing is more flexible and easier to straighten, while rigid copper tubing may require more effort and specialized tools. Assessing the condition of the tubing helps you choose the most appropriate straightening approach.

3. Using a Tubing Bender

A tubing bender is a specialized tool designed specifically for shaping and straightening copper tubing. To use a tubing bender, insert the bent section of the tubing into the appropriate-sized groove on the bender. Apply steady pressure to the handle of the bender, gradually bending the tubing in the desired direction. Move the tubing through the bender in small increments, adjusting the angle as needed to achieve the desired straightness. Tubing benders are available in various sizes and shapes to accommodate different tubing diameters and bending radii.

4. Using a Spring Bender

A spring bender is another tool commonly used to straighten copper tubing, especially in confined spaces or tight bends. A spring bender consists of a coiled spring that fits around the tubing and helps guide it into a straighter shape. To use a spring bender, slide the coiled spring over the bent section of the tubing and gradually push or pull it along the length of the tubing. The spring helps distribute the force evenly, reducing the risk of further bending or kinking. Spring benders come in various sizes to accommodate different tubing diameters and lengths.

5. Applying Manual Force

For minor bends or kinks in soft copper tubing, manual force may be sufficient to straighten the tubing. Gently grasp the bent section of the tubing with your hands and apply pressure in the opposite direction of the bend. Slowly work your way along the length of the tubing, gradually straightening out any curves or kinks. Be careful not to apply too much force, as this could cause the tubing to deform further or develop new bends. Manual force is a simple yet effective method for straightening soft copper tubing in small-scale applications.

6. Using a Vice Grip

A vice grip, also known as locking pliers or mole grips, can be used to straighten copper tubing by applying controlled pressure to the bent section. Clamp the jaws of the vice grip around the bent portion of the tubing, ensuring a firm grip without crushing or damaging the tubing. Use the handles of the vice grip to apply gentle pressure in the opposite direction of the bend, gradually straightening out the tubing.

Move the vice grip along the length of the tubing as needed to address any remaining bends or kinks. Using a vice grip provides precise control and allows you to adjust the straightening force as necessary.

7. Applying Heat

In some cases, applying heat to the bent section of the tubing can help soften the metal and make it more pliable, facilitating the straightening process. Use a propane torch or heat gun to heat the bent area of the tubing until it becomes red-hot or visibly softened. Once the metal is heated, quickly straighten the tubing using a tubing bender, spring bender, or manual force. Be careful when applying heat to copper tubing, as excessive heat can cause discoloration, oxidation, or annealing of the metal. Use heat sparingly and apply it only to the bent section of the tubing.

8. Using a Pipe Straightening Tool

A pipe straightening tool is a specialized device designed to straighten copper tubing quickly and efficiently. This tool typically consists of a pair of clamping jaws that grip the tubing and a lever or handle that applies controlled force to straighten it. To use a pipe straightening tool, place the bent section of the tubing between the jaws of the tool and tighten the clamps securely. Use the lever or handle to apply pressure, gradually straightening out the tubing. Pipe straightening tools are available in various sizes to accommodate different tubing diameters and lengths.

9. Applying Mechanical Tension

Mechanical tension can be used to straighten copper tubing by stretching it along its length and removing any bends or kinks. Secure one end of the tubing to a fixed object, such as a wall or workbench, using a clamp or vice grip. Apply tension to the free end of the tubing by pulling it in the opposite direction of the bend. Slowly increase the tension until the tubing begins to straighten out, adjusting the position of the clamp as needed to maintain tension along the length of the tubing.

Applying mechanical tension helps remove bends and kinks from the tubing, restoring it to a straight and uniform shape.

10. Using Hydraulic Straightening Equipment

For large-scale or industrial applications, hydraulic straightening equipment can be used to straighten copper tubing efficiently and accurately. Hydraulic straighteners utilize hydraulic pressure to apply controlled force to the tubing, straightening it with precision and consistency. To use hydraulic straightening equipment, secure the tubing in the straightening machine and adjust the settings to apply the desired amount of pressure.

Activate the hydraulic mechanism to gradually straighten the tubing, monitoring the process closely to ensure optimal results. Hydraulic straightening equipment is ideal for straightening long lengths of tubing or tubing with complex bends and curves.

Conclusion

Straightening copper tubing is a fundamental skill that is essential for various plumbing, HVAC, and mechanical applications. By following these ten comprehensive methods, you can straighten copper tubing effectively and achieve professional results. Understanding the properties of copper tubing, assessing the condition of the tubing, and selecting the appropriate straightening method are essential preparatory steps.

Whether using a tubing bender, spring bender, vice grip, or hydraulic straightening equipment, each method offers unique advantages and applications for straightening copper tubing. With proper techniques and equipment, you can ensure the tubing is straight, uniform, and free of bends or kinks, allowing for optimal performance and longevity in your plumbing or mechanical systems. Be sure to follow all instructions on how to straighten copper tubing carefully, and always consult an expert when in doubt.